7 Essential Benefits of Choosing Thermoplastic Rubber for Your Next Project

In recent years, the construction and manufacturing industries have increasingly recognized the advantages of using Thermoplastic Rubber (TPR) for various applications. According to a report by the Freedonia Group, the demand for thermoplastic elastomers is projected to reach $24 billion by 2025, driven by their unique properties and versatility. TPR combines the best of both rubber and plastic, delivering exceptional elasticity, durability, and recyclability. This makes it an ideal choice for everything from automotive components to consumer products. As we explore the seven essential benefits of choosing Thermoplastic Rubber for your next project, we will highlight how its superior performance characteristics can enhance product longevity, reduce costs, and contribute to sustainability initiatives, providing a compelling case for its integration in modern manufacturing practices.

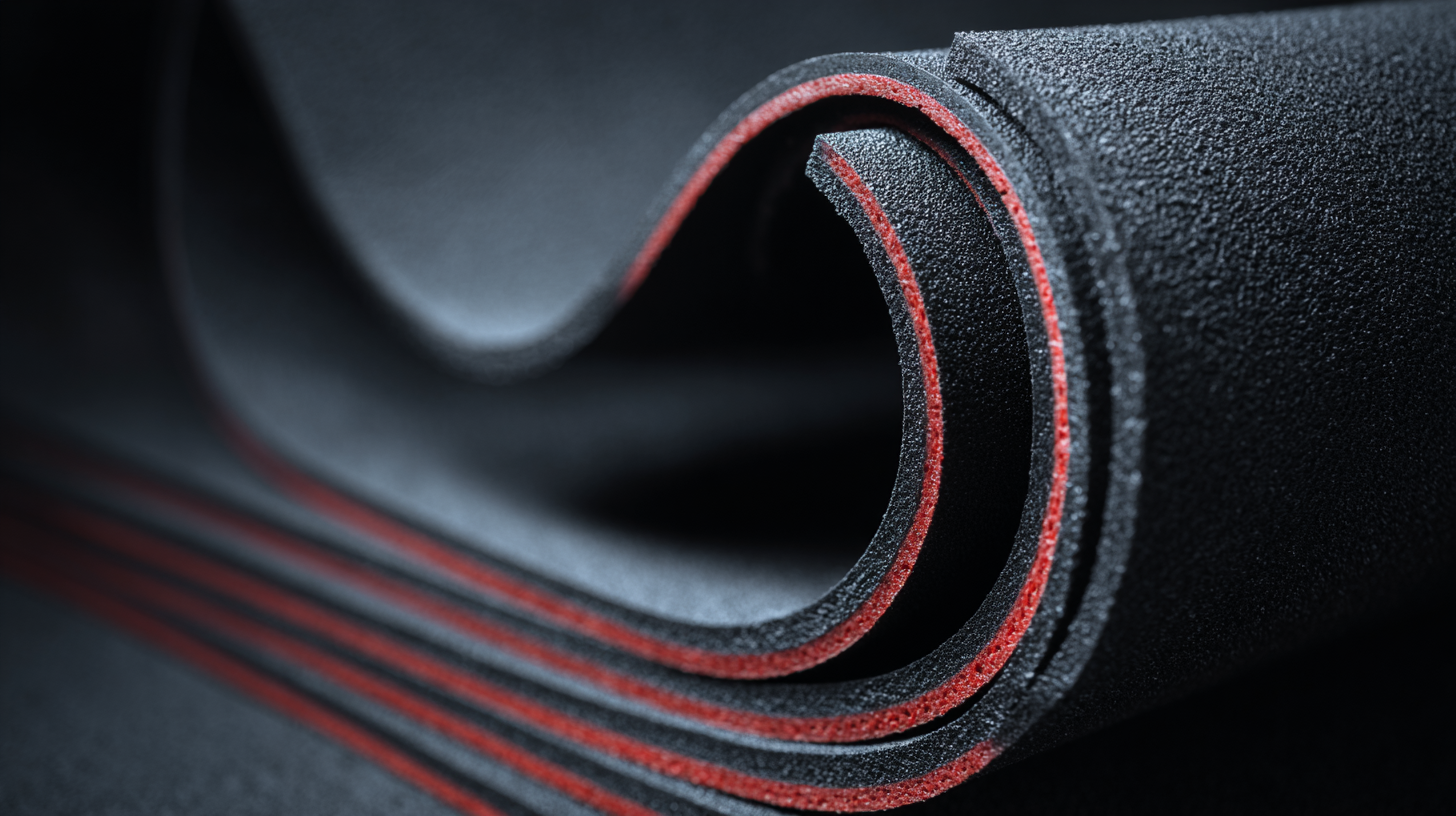

Advantages of Thermoplastic Rubber: A Versatile Material for Engineering Projects

Thermoplastic rubber (TPR) is increasingly recognized as a versatile material in engineering projects, primarily due to its excellent physico-chemical properties. TPR combines the beneficial characteristics of both thermoplastics and elastomers, providing enhanced flexibility, resilience, and durability. According to recent industry reports, TPR exhibits high impact resistance and tensile strength, which makes it ideal for applications such as automotive parts, footwear, and various consumer goods. The material's ability to withstand extreme temperatures and chemicals also adds to its appeal, promoting longevity and reliability in diverse environments.

Moreover, the eco-friendly aspect of TPR is gaining attention in the context of sustainable engineering practices. As the demand for green materials grows, TPR stands out due to its potential for recycling and reusability. Recent studies have shown that incorporating natural fibers into TPR composites can further enhance their mechanical properties while reducing environmental impact. The use of natural reinforcements like jute and flax not only contributes to a lower carbon footprint but also offers a renewable alternative to conventional materials. This alignment with sustainability goals makes thermoplastic rubber a compelling choice for future engineering projects focused on innovation and environmental responsibility.

Cost-Effectiveness of Thermoplastic Rubber in Manufacturing Processes

When it comes to manufacturing processes, cost-effectiveness is a critical factor that significantly influences material selection. Thermoplastic rubber (TPR) emerges as a viable solution that balances affordability with performance. Its unique properties allow for efficient production methods, which in turn help reduce labor and material costs. TPR can be easily molded and formed, enabling manufacturers to streamline their operations and minimize waste, thus enhancing overall productivity.

Moreover, TPR's durability and versatility translate into long-term savings. Unlike traditional rubber, thermoplastic rubber can withstand harsh environments without degrading, leading to lower replacement and maintenance costs over time. The ease of recycling TPR adds an additional layer of economic advantage, as it can be reused in new applications, further reducing waste disposal expenses. In a landscape where sustainability and cost management are paramount, opting for thermoplastic rubber can result in significant savings and operational efficiencies for manufacturers looking to innovate in their projects.

Durability and Longevity: Why Thermoplastic Rubber Outperforms Other Materials

When it comes to selecting materials for various projects, thermoplastic rubber (TPR) stands out due to its exceptional durability and longevity. Unlike traditional materials, TPR can withstand extreme temperature variations and harsh environmental conditions, making it an ideal choice for automotive applications, where resilience is crucial. Its flexibility allows it to absorb shocks effectively, resulting in better performance and extended lifespans for components made from this innovative material.

Moreover, as the industry shifts towards more sustainable practices, thermoplastic rubber offers a compelling alternative. While natural fiber composites are recognized for their eco-friendly attributes and are gaining traction, TPR still holds significant advantages in terms of versatility and process efficiency. The advancements in TPR technology continue to push the boundaries of material performance, ensuring that manufacturers can rely on TPR not only for durability but also for the environmentally conscious imperatives of modern production standards. This combination of strength and sustainability positions thermoplastic rubber as a material of choice for forward-thinking projects across various sectors.

Environmental Impact: The Sustainability of Choosing Thermoplastic Rubber

As industries increasingly prioritize sustainability, thermoplastic rubber (TPR) emerges as a formidable choice, demonstrating substantial environmental benefits. A study published by the Association of Rubber Products Manufacturers (ARPM) indicates that TPR can be recycled more effectively than traditional rubber, with an estimated 50-100% of its material being reclaimable after use. This not only reduces waste but also lessens the demand for new raw materials, thereby conserving natural resources. The lifecycle of TPR, which tends to be longer due to its resistance to wear and tear, further enhances its appeal to environmentally conscious manufacturers.

Moreover, the production of TPR involves less energy-intensive processes compared to other materials, as reported by the Renewable Resources Coalition. By utilizing TPR, companies can significantly lower their carbon footprint—up to 20% less energy consumption during manufacturing has been observed. These impressive figures underscore TPR's role in promoting a circular economy, where products are designed for durability and recyclability. As sustainability becomes paramount, the choice of thermoplastic rubber not only benefits individual projects but also contributes positively to broader environmental goals.

Environmental Impact of Thermoplastic Rubber vs. Traditional Materials

This bar chart illustrates the environmental impacts of Thermoplastic Rubber compared to traditional materials across four key factors: carbon footprint, waste production, recyclability, and energy consumption. Lower values indicate a more sustainable choice, highlighting the benefits of Thermoplastic Rubber in reducing environmental impact.

Design Flexibility: Customization Opportunities with Thermoplastic Rubber Solutions

Thermoplastic rubber (TPR) solutions are revolutionizing the design landscape, offering unmatched customization opportunities for various applications. As the thermoplastic elastomers market is projected to expand from USD 30.83 billion in 2025 to USD 38.94 billion by 2030, the significance of flexibility in design becomes increasingly clear. Challenges in unique product formulation and production methods are being met by innovations in TPR, allowing manufacturers to tailor materials according to specific project requirements.

The versatility of thermoplastic rubber enables designers to explore a wide array of textures, colors, and functional properties. Liquid silicone rubber seals, for example, play a substantial role in modern manufacturing, showcasing the ability to adapt to demanding specifications. This adaptability not only enhances product performance but also opens avenues for creative solutions in industries ranging from automotive to consumer goods. As the market for thermoplastic polyurethanes, particularly in footwear, anticipates growth from USD 1.12 billion in 2024, it's evident that the industry is embracing design flexibility as a crucial component in meeting consumer demands and driving innovation forward.

7 Essential Benefits of Choosing Thermoplastic Rubber for Your Next Project

| Benefit | Description | Customization Opportunities |

|---|---|---|

| Design Flexibility | Thermoplastic rubber offers excellent design flexibility, allowing for intricate shapes and forms. | Custom molds can be created to achieve unique designs. |

| Durability | Highly resistant to wear, weathering, and UV exposure. | Color and finish customization enhance durability factors. |

| Lightweight | Lighter than many traditional materials, reducing overall project weight. | Custom thickness options can be specified for weight management. |

| Versatility | Suitable for a wide range of applications across industries. | Tailored formulations can be produced for specific industry needs. |

| Ease of Processing | Can be easily molded, extruded, or fabricated into complex shapes. | Custom processing techniques can be applied based on the project. |

| Cost-Effective | Lower production costs compared to some alternative materials. | Custom batch sizes can optimize costs for different project scales. |

| Recyclability | Can be recycled, reducing environmental impact. | Customized recycling options can be developed for specific products. |

Related Posts

-

Top 10 Thermoplastic Rubber Manufacturers from China at the 137th Canton Fair

-

Top Strategies for Sourcing the Best Thermoplastic Rubber to Maximize Your Supply Chain Efficiency

-

Exploring Sustainable Alternatives to Best Natural Gum Rubber for Global Buyers

-

Chinese Factories Leading the Way to Global Trust with Best Nbr Solutions

-

Tpr Rubber Market Insights and Trends for Global Buyers in 2025

-

Exploring Butyl Rubber Innovations Shaping Global Supply Chains in 2025