What is Normal Butyl Rubber and its Applications?

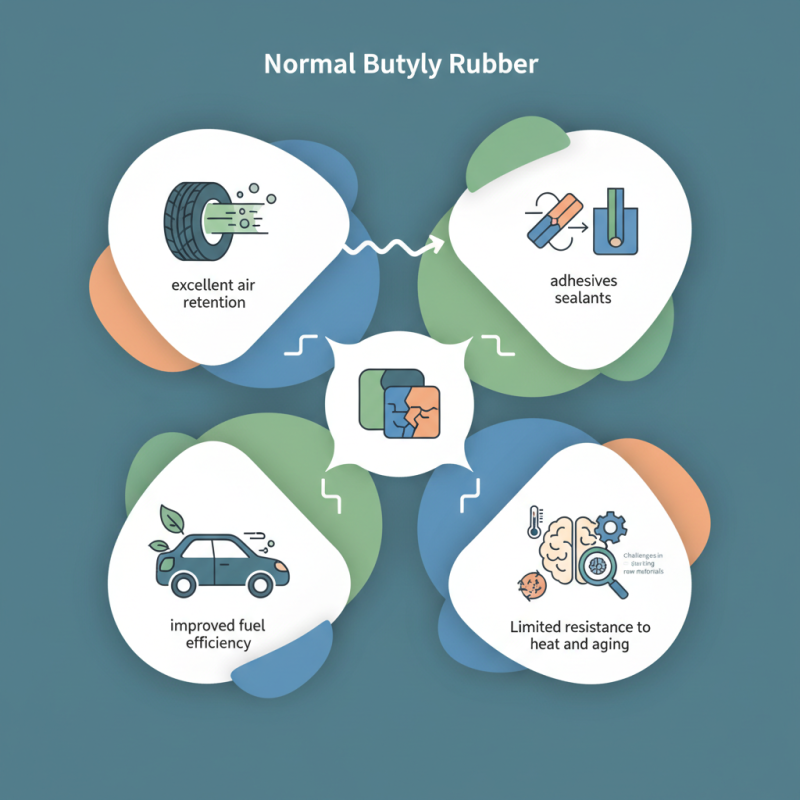

Normal Butyl Rubber is a versatile synthetic rubber. It is widely used in various industries due to its unique properties. This rubber excels in providing excellent air retention and flexibility.

Its applications can be found in tires, adhesives, and sealants. In the automotive sector, Normal Butyl Rubber contributes to improved fuel efficiency. Many companies rely on it for manufacturing high-quality products. However, challenges exist in sourcing raw materials.

While it offers many advantages, not every application is perfect. For instance, its resistance to heat and aging can be limited compared to other rubbers. Understanding these aspects is essential for manufacturers. Constant innovation is needed to enhance its performance and address limitations.

What is Normal Butyl Rubber?

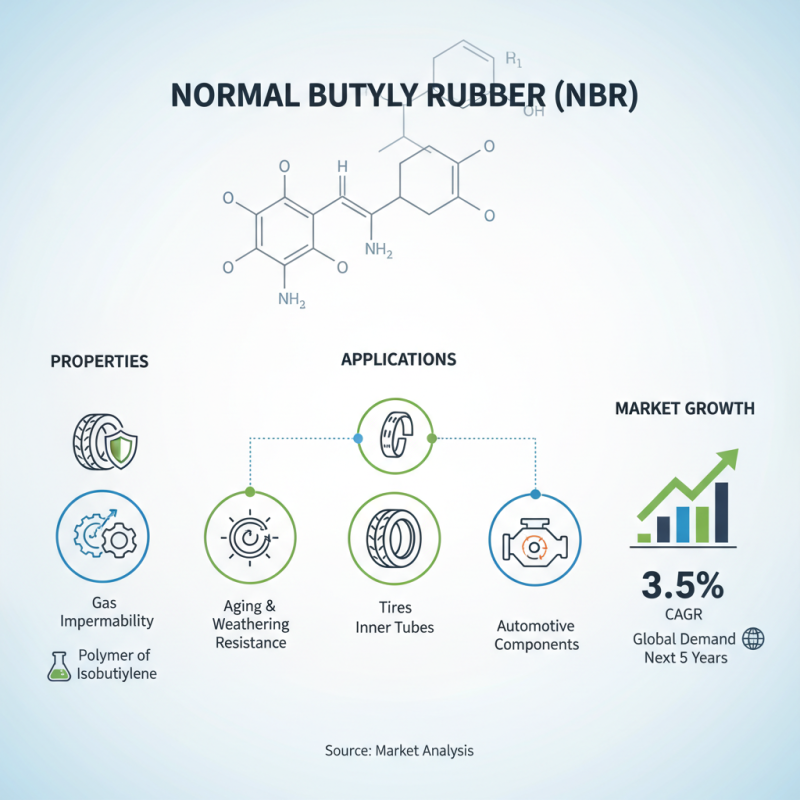

Normal butyl rubber (NBR) widely finds applications in various industries due to its unique properties. Produced through the polymerization of isobutylene, it offers excellent gas impermeability and superior resistance to aging and weathering. This makes NBR a preferred choice for manufacturing tires, inner tubes, and automotive components. According to market analysis, the global demand for NBR is projected to grow at a CAGR of 3.5% over the next five years.

In addition to automotive use, NBR serves in medical applications. It is used for gloves and syringes, ensuring a sterile environment. The rubber shows significant resistance to chemicals and maintains flexibility under various conditions. However, challenges exist in processing and recycling NBR. Many manufacturers face hurdles in creating environmentally friendly disposal methods.

Tips: When working with NBR, consider proper storage conditions. NBR can degrade if exposed to direct sunlight for extended periods. Additionally, regular maintenance of NBR products ensures longevity. Awareness of the rubber’s limitations is crucial for optimal performance.

Chemical Structure and Properties of Normal Butyl Rubber

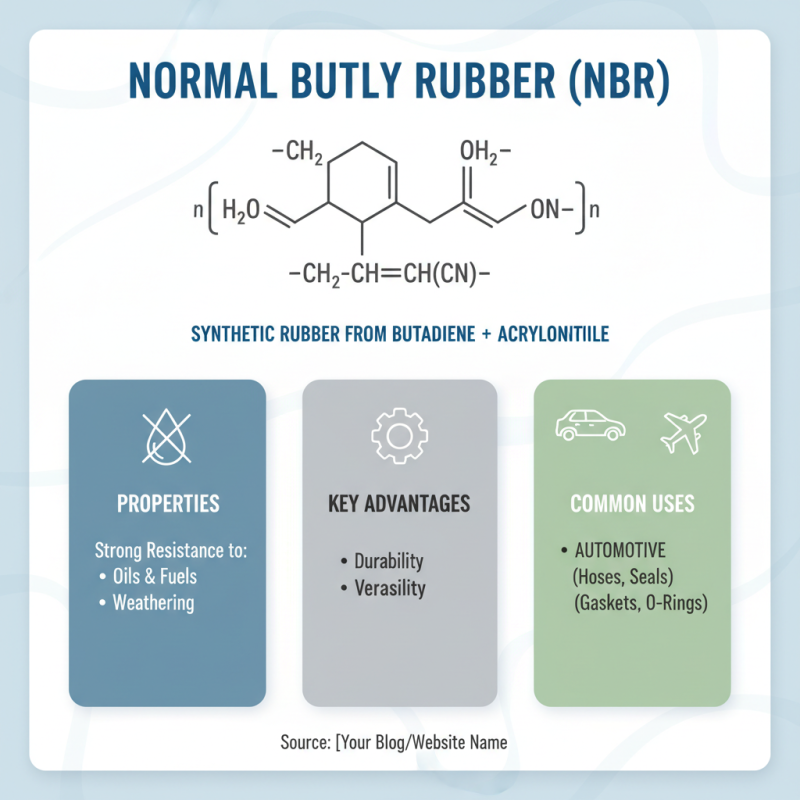

Normal butyl rubber (NBR) is a synthetic rubber derived from the polymerization of butadiene and acrylonitrile. Its unique chemical structure gives it specific properties that make it highly valuable. NBR has strong resistance to oils, fuels, and weathering. This makes it a popular choice in various industries, from automotive to aerospace.

The structure of NBR consists of alternating butadiene and acrylonitrile units. This composition contributes to its excellent tensile strength and resilience. Research shows that NBR can withstand temperatures ranging from -40°C to 100°C. Due to its low permeability to gases, it is also ideal for sealing applications.

**Tip:** When selecting NBR for a project, consider its durometer hardness. This affects flexibility and strength.

NBR is essential in producing gaskets, hoses, and seals. It can also be blended with other materials to improve its performance. However, its resistance to ozone is limited. UV exposure can degrade NBR over time, which may present challenges in outdoor applications.

**Tip:** Regular inspections can prevent early material failure in outdoor uses.

Manufacturing Process of Normal Butyl Rubber

Normal Butyl Rubber (NBR) is a synthetic rubber. The manufacturing process is key to its performance. The primary raw material for NBR is the polymerization of isobutylene. This gas is combined with isoprene in a controlled environment.

During production, temperatures need to be maintained precisely. If it's too hot, the rubber won't set properly. Too cold and the polymer chain will break. The process often includes a catalyst to speed up reactions. This is where chemistry plays a crucial role.

Tips: Always measure conditions carefully. Small changes can lead to different outcomes. Understand the materials used thoroughly. Poor quality inputs can affect the rubber's properties.

After polymerization, the rubber undergoes additional processes. These may include mixing with fillers and stabilizers. These additives enhance its strength and durability. The final product has extensive applications. It’s used in tire manufacturing, sealants, and medical devices. Nevertheless, even experienced manufacturers can face inconsistencies. Each batch may vary slightly in properties. Keeping a close eye on the process is essential.

What is Normal Butyl Rubber and its Applications? - Manufacturing Process of Normal Butyl Rubber

| Property | Value |

|---|---|

| Chemical Structure | Polyisobutylene (C4H8)n |

| Molecular Weight | Approximately 30,000 - 1,000,000 g/mol |

| Key Properties | Low gas permeability, excellent aging resistance, good flexibility |

| Applications | Tires, sealants, adhesives, coatings, and rubber products |

| Manufacturing Process | Polymerization of isobutylene in the presence of a catalyst |

| Temperature Range | -30°C to 80°C |

| Environmental Resistance | Resistant to UV and ozone |

Key Applications of Normal Butyl Rubber in Various Industries

Normal Butyl Rubber (NBR) plays a significant role in various industries. Its unique properties make it a popular choice for several applications. NBR has excellent air retention, which is crucial for tire manufacturing. It provides durability and flexibility, making it ideal for rubber products.

In the automotive sector, NBR is often used for sealing materials, hoses, and grommets. These components need to withstand varying temperatures and pressures. NBR excels in such conditions. It is resistant to aging and environmental stresses. Additionally, the construction industry employs NBR in adhesives and coatings. These products require strong performance under harsh conditions.

Tips: Always check the compatibility of NBR with other materials. Testing is essential to avoid future issues during application. Make sure to keep samples for quality assessments.

The medical field benefits from NBR as well. It is used for gloves and other equipment. However, quality control is crucial. Some batches may vary in strength and elasticity; thus, thorough testing is necessary. Understanding these nuances can help in making better choices.

Normal Butyl Rubber Applications in Various Industries

Advantages and Limitations of Using Normal Butyl Rubber

Normal butyl rubber, often abbreviated as IIR, is a synthetic elastomer. It is produced through the polymerization of isobutylene. One of its main advantages is its excellent air impermeability. This makes it ideal for applications like tire inner linings and inflatable products. Butyl rubber also exhibits good resistance to ozone and UV radiation. These properties help enhance the durability of products used in harsh environments.

However, there are limitations to consider. Butyl rubber has lower tensile strength compared to some other elastomers. This can lead to premature wear in dynamic applications. Additionally, it may not adhere well to certain substrates. This limits its use in bonding applications. Its cost can also be a concern; while it provides good insulation, the price may be higher than alternative materials.

In applications requiring flexibility, butyl rubber may fall short. The material tends to be less elastic, which might not suit every need. Manufacturers must weigh these factors carefully. The effectiveness of normal butyl rubber relies heavily on the specific requirements of each application.

Related Posts

-

Exploring Butyl Rubber Innovations Shaping Global Supply Chains in 2025

-

How to Optimize the Use of Normal Butyl Rubber for Enhanced Industrial Performance

-

Top 10 Benefits and Uses of Butyl Rubber in Various Industries

-

Unlocking the Potential of Butyl Rubber for Global Suppliers

-

Comprehensive Resource on Normal Butyl Rubber for Global Buyers in 2023

-

Exploring the Versatility and Applications of Best Santoprene Rubber in Diverse Industries