Solutions for Achieving Optimal Performance with Best Santoprene Rubber

In today's competitive landscape, industries are increasingly turning to advanced materials to enhance performance and efficiency, with Santoprene Rubber emerging as a preferred choice. This thermoplastic elastomer, known for its remarkable resilience and versatility, has gained significant traction across various sectors. According to a recent market analysis by Smithers Pira, the global thermoplastic elastomers market is projected to exceed $26 billion by 2025, with Santoprene Rubber accounting for a substantial share due to its superior elasticity and weather resistance. As manufacturers seek solutions to improve product durability and reduce costs, understanding the optimal applications and processing techniques for Santoprene Rubber is essential. This article delves into effective strategies for leveraging Santoprene Rubber's unique properties to achieve optimal performance, ensuring businesses remain competitive while meeting evolving consumer demands.

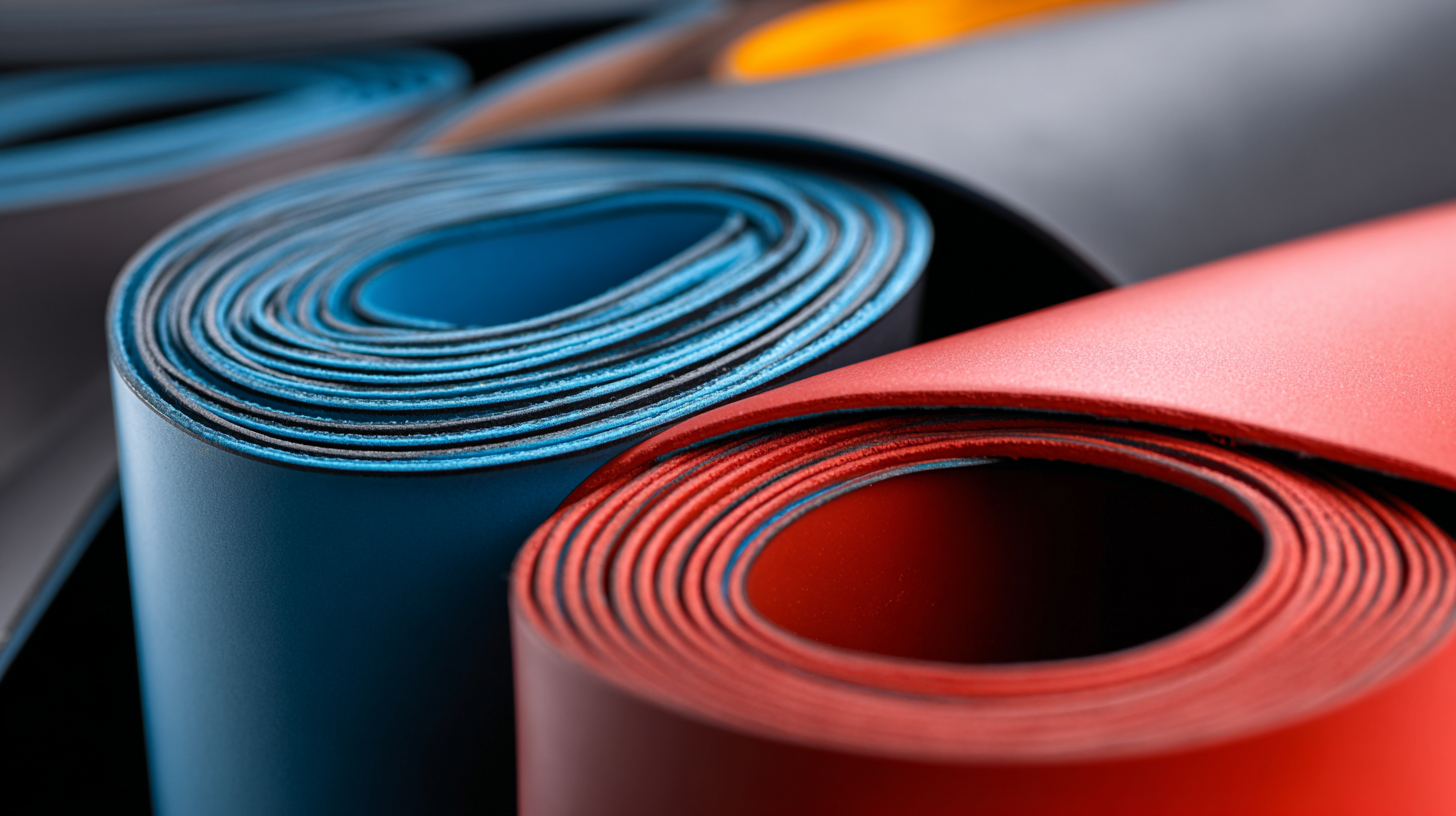

Exploring the Versatility of Santoprene Rubber in Industrial Applications

Santoprene rubber, a type of thermoplastic vulcanizate (TPV), is gaining traction in a variety of industrial applications due to its exceptional versatility and performance characteristics. The recent acquisition of the Santoprene TPV business signifies a renewed focus on this high-performance material, which is increasingly utilized in automotive, consumer goods, and industrial applications. According to industry reports, the global market for TPVs is projected to reach $2.5 billion by 2025, highlighting a significant growth opportunity driven by innovations in material science and the heightened demand for sustainable solutions.

In automotive applications, Santoprene rubber is particularly favored for its durability and resistance to environmental stressors. It combines the benefits of rubber's elasticity with the recyclability and processing simplicity of thermoplastics. A study highlighted that materials like Santoprene can withstand extreme temperatures and harsh chemicals, making them ideal for components such as gaskets, seals, and boots. As manufacturers increasingly prioritize sustainability, the ability of Santoprene to be recycled and reused is crucial, aligning with industry trends towards eco-friendliness and reduced lifecycle impacts.

Furthermore, Santoprene's adaptability extends beyond automotive uses. Its application has broadened to include consumer products, healthcare, and industrial machinery, where its properties can be fine-tuned to meet specific performance requirements. The continued investment in Santoprene technology reflects a strategic shift towards versatile materials that can fulfill the demands of modern manufacturing processes, paving the way for innovative applications across various sectors.

Key Properties of Santoprene Rubber that Enhance Performance and Durability

Santoprene rubber is renowned for its unique properties that significantly enhance performance and durability in various applications. One of its key features is its excellent elasticity, allowing it to return to its original shape after deformation, which is crucial for products requiring repeated flexing and bending. Additionally, Santoprene exhibits remarkable resistance to aging and environmental factors, including UV radiation and ozone, making it an ideal choice for outdoor applications. Its superior chemical resistance further extends its usability in diverse industries, ensuring longevity in high-demand environments.

In the rubber processing oil market, the growth and diversity of applications drive the demand for high-performance materials, such as Santoprene. With segments including tires, footwear, rubber compounding, and belts, the versatility of Santoprene makes it an essential material in these areas. Its compatibility with various processing oils, such as paraffinic, naphthenic, and TDAE oils, enhances its processing capabilities and overall performance. As the market continues to expand from 2024 to 2031, the adoption of Santoprene rubber is expected to rise, influenced by its ability to meet stringent performance standards while maintaining durability across different regional markets.

Key Properties of Santoprene Rubber that Enhance Performance and Durability

This bar chart illustrates the key properties of Santoprene rubber and their respective contributions to performance and durability. The properties measured include Elasticity, Temperature Resistance, Chemical Resistance, UV Stability, and Abrasion Resistance.

Comparative Analysis: Santoprene Rubber vs. Traditional Elastomers in Manufacturing

When it comes to manufacturing, the choice of materials can significantly impact product performance and longevity. Santoprene rubber, a thermoplastic elastomer, is often compared to traditional elastomers like natural rubber and silicone. According to a report by MarketsandMarkets, the global thermoplastic elastomer market is projected to reach USD 23.29 billion by 2024, driven by the increasing demand for high-performance materials in various industries such as automotive and consumer goods.

Santoprene stands out due to its superior elasticity, chemical resistance, and performance stability, making it an ideal choice for products that require both flexibility and durability.

In contrast, traditional elastomers often exhibit limitations in terms of thermal and environmental resistance. For instance, natural rubber has lower ozone resistance, which can lead to premature degradation when exposed to certain atmospheric conditions. A study conducted by the Rubber Division of the American Chemical Society found that Santoprene not only retains its mechanical properties over time but also shows less sensitivity to temperature fluctuations. This comparative advantage allows manufacturers to reduce replacement cycles and maintenance costs, positioning Santoprene as a more efficient choice for high-performance applications where reliability is crucial.

Global Market Trends: The Growth of Santoprene Rubber in Export Industries

The global market for synthetic polyisoprene rubber is projected to reach USD 7.75 billion by 2034, growing at a compound annual growth rate (CAGR) of 9.05%. This surge is driven by increasing demand across various export industries, particularly in automotive, healthcare, and consumer goods. Synthetic polyisoprene offers unique properties such as elasticity and durability, making it a preferred choice over traditional rubber alternatives.

As industries continue to invest in innovative materials, the growth trajectory of Santoprene rubber becomes particularly noteworthy. The versatility of Santoprene rubber in applications ranging from automotive seals to medical devices highlights its expanding role in meeting the demands of a rapidly evolving market. With the global push towards sustainability, Santoprene rubber's eco-friendly characteristics further solidify its position in future market trends. Continuous advancements in manufacturing processes are expected to enhance its performance and broaden its application scope, subsequently driving market growth and attracting investments in the sector.

Best Practices for Selecting and Implementing Santoprene Rubber Solutions in Production

When it comes to selecting Santoprene rubber for production, understanding its unique properties is essential. Santoprene, known for its excellent thermal stability, chemical resistance, and flexibility, can be an ideal choice for various applications. However, it’s crucial to assess the specific requirements of your project. Factors such as environmental exposure, load-bearing capacity, and desired aesthetic should guide your selection process. Engaging with suppliers who can provide detailed information on the different grades of Santoprene can help in matching the right type to your production needs.

Implementing Santoprene solutions effectively requires attention to processing techniques. The rubber may require specialized molding or extrusion methods to achieve optimal results. It’s advisable to conduct thorough testing during the prototyping phase to identify any potential issues early on. Additionally, investing time in training your production team on the best practices for handling Santoprene can greatly enhance efficiency and product quality. By combining informed selection with skilled implementation, manufacturers can leverage Santoprene’s full potential, resulting in superior performance and durability in their end products.