Exploring the Versatility of Styrene Butadiene Rubber: Applications and Innovations in Today's Industry

Styrene Butadiene Rubber (SBR) has emerged as a cornerstone material in various industrial applications, owing to its remarkable versatility and performance characteristics. According to a report by Grand View Research, the global SBR market was valued at approximately $7.4 billion in 2021 and is projected to expand at a compound annual growth rate (CAGR) of 4.8% from 2022 to 2030. This growth can be attributed to the material's exceptional properties, including durability, heat resistance, and excellent abrasion resistance, making it ideal for use in rubber tires, automotive components, and various consumer products. Moreover, recent innovations in the synthesis and compounding of Styrene Butadiene Rubber are constantly enhancing its performance, enabling industries to meet evolving demands for sustainability and efficiency. As we delve into the applications and innovations surrounding SBR, it becomes clear that this material not only plays a critical role in current industrial practices but also paves the way for future advancements in materials technology.

The Chemical Composition and Properties of Styrene Butadiene Rubber

Styrene Butadiene Rubber (SBR) is a synthetic rubber that has gained prominence due to its unique chemical composition and favorable properties. Composed of styrene and butadiene monomers, SBR exhibits a balance between rigidity and elasticity, making it suitable for a variety of applications. The styrene component imparts strength and durability, while the butadiene component contributes to its flexibility and resilience. This combination results in a material that can withstand wear while maintaining its shape, crucial for many industrial applications.

One of SBR's key properties is its exceptional abrasion resistance, which makes it ideal for use in tires and other automotive components. Additionally, its resistance to aging and environmental factors enhances its longevity, further expanding its range of applications. The versatility of SBR is evident in sectors such as footwear, adhesives, and coatings, where its unique balance of performance and cost-effectiveness offers significant advantages. As industries continue to innovate, the demand for SBR remains strong, driving advancements in its formulation and processing techniques to optimize its performance for emerging applications.

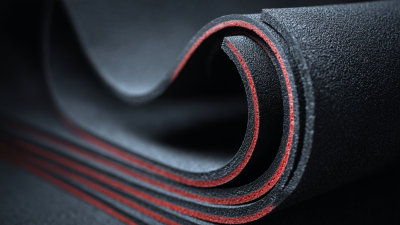

Key Applications of Styrene Butadiene Rubber in the Automotive Sector

Styrene Butadiene Rubber (SBR) has become an essential material in the automotive sector, thanks to its impressive balance of flexibility, durability, and resistance to heat and abrasion. As the global automotive market evolves, the demand for high-performance materials like SBR is expected to grow significantly. According to recent market growth reports, the global SBR market is projected to expand from approximately $4.67 billion in 2023 to about $6.25 billion by 2030, representing a compound annual growth rate (CAGR) of 4.2%. This growth reflects the ongoing innovations and applications of SBR in various automotive components.

One of the key applications of SBR in the automotive industry includes its use in tires. The material’s excellent wear resistance and aging stability make it ideal for manufacturing high-performance tires that can withstand various road conditions. Additionally, SBR is widely used in the production of seals and gaskets, providing crucial functionalities that enhance overall vehicle performance and longevity. The adoption of SBR in these applications not only improves product performance but also aligns with the industry's shift toward more sustainable and efficient manufacturing processes, making it a versatile choice for numerous automotive endeavors.

Key Applications of Styrene Butadiene Rubber in the Automotive Sector

Innovative Techniques for Enhancing Styrene Butadiene Rubber Performance

Innovative techniques are pivotal in enhancing the performance of Styrene Butadiene Rubber (SBR), a material renowned for its adaptability across various industries. One prominent approach involves the incorporation of nanomaterials to improve mechanical properties and thermal stability. By integrating nanoparticles, such as carbon nanotubes or silica, manufacturers can significantly enhance the elasticity and tensile strength of SBR, making it an ideal choice for demanding applications in automotive tires and industrial seals.

Innovative techniques are pivotal in enhancing the performance of Styrene Butadiene Rubber (SBR), a material renowned for its adaptability across various industries. One prominent approach involves the incorporation of nanomaterials to improve mechanical properties and thermal stability. By integrating nanoparticles, such as carbon nanotubes or silica, manufacturers can significantly enhance the elasticity and tensile strength of SBR, making it an ideal choice for demanding applications in automotive tires and industrial seals.

Additionally, advancements in polymer blending techniques have led to the development of hybrid rubber compounds that combine the benefits of SBR with other elastomers. These innovative blends offer superior resistance to wear and aging, further broadening the range of applications. Moreover, cross-linking methods, such as gamma radiation or chemical cross-linkers, have been utilized to enhance the structural integrity of SBR, resulting in products that can withstand harsh environmental conditions while maintaining their desired flexibility and durability. Such innovations not only optimize the performance of Styrene Butadiene Rubber but also promote sustainability by extending the lifecycle of products made from this versatile material.

Market Trends: Growth Forecast for Styrene Butadiene Rubber in Various Industries

The styrene butadiene rubber (SBR) market is experiencing significant growth, driven by its diverse applications across multiple industries. According to a recent report by MarketsandMarkets, the global SBR market is projected to reach USD 6.2 billion by 2025, expanding at a compound annual growth rate (CAGR) of 4.4% from 2020. This growth is primarily attributed to the increasing demand from the automotive sector, where SBR is prized for its excellent abrasion resistance and tensile strength, making it ideal for tires and seals.

Moreover, the construction and footwear industries are also showing a growing interest in SBR, contributing to its market expansion. The report highlights that the construction sector alone is expected to account for a significant share of SBR consumption due to its use in adhesives and sealants. Furthermore, as the shift towards sustainable materials continues, innovations in SBR formulations, such as bio-based and recycled SBR, are gaining traction, poised to drive further market growth. This trend indicates that SBR will play a pivotal role in meeting future industry demands, showcasing its versatility and adaptability in various applications.

Sustainability Efforts and Eco-Friendly Practices in Styrene Butadiene Rubber Production

The production of Styrene Butadiene Rubber (SBR) has seen significant advancements towards sustainability, aligning with global efforts to minimize environmental impacts. According to a recent report by Grand View Research, the global SBR market is projected to reach USD 9.29 billion by 2025, emphasizing the heightened demand for eco-conscious manufacturing processes. Manufacturers are increasingly adopting eco-friendly practices such as utilizing bio-based feedstocks and implementing energy-efficient production methods. This shift not only reduces carbon footprints but also appeals to environmentally-aware consumers and businesses.

Moreover, the industry is witnessing innovations in waste management and recycling processes. The European Tyre and Rubber Manufacturers Association (ETRMA) states that over 80% of tire materials, predominantly SBR, can be recycled. This creates a circular economy within the rubber sector, promoting the reuse of materials and minimizing landfill contributions. Companies are now investing in advanced technologies that facilitate the recovery of SBR from used tires, paving the way for a more sustainable future in rubber production. By embracing these practices, the SBR industry is not only enhancing its ecological profile but also setting a benchmark for other sectors to follow.

Exploring the Versatility of Styrene Butadiene Rubber: Applications and Innovations in Today's Industry

| Application Area | Key Features | Innovations | Sustainability Practices |

|---|---|---|---|

| Tires | High abrasion resistance, low rolling resistance | Developing bio-based SBR blends | Use of recycled materials in production |

| Adhesives | Strong bonding, flexibility | Water-based adhesive formulations | Low VOC emissions in adhesives |

| Sealants | Weather resistant, excellent adhesion | Hybrid sealant technologies | Bio-based polymers for eco-friendliness |

| Footwear | Comfort, durability | Innovative molding techniques | Sustainable sourcing of materials |

| Automotive parts | High strength, lightweight | Advanced compound formulations | Life cycle assessment for material selection |

Related Posts

-

How to Leverage High Cis Polybutadiene for Enhanced Product Performance

-

Solutions for Sourcing the Best Butadiene Rubber Globally

-

7 Essential Benefits of Choosing Thermoplastic Rubber for Your Next Project

-

How China's Best Kalrez Rubber Sets New Standards for Global Quality and Trust

-

Ultimate Guide to Mastering Ultrasonic Welding Rubber Techniques and Applications

-

Chinese Factories Leading the Way to Global Trust with Best Nbr Solutions