7 Essential Tips for Optimizing Injection Molding Nitrile Rubber Production

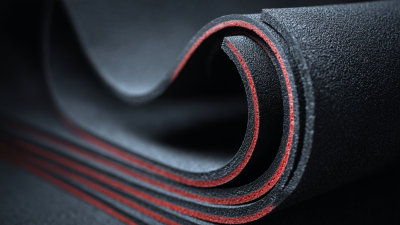

In the competitive landscape of manufacturing, optimizing production processes has become indispensable for achieving efficiency and quality. Injection Molding Nitrile Rubber, recognized for its superior resistance to oils and temperatures, has garnered attention in various industries, including automotive, aerospace, and medical. According to a recent report by Grand View Research, the global nitrile rubber market is projected to reach USD 2.95 billion by 2025, signifying a growing demand for high-performance materials. However, as production scales up, manufacturers face challenges related to material waste, cycle times, and overall cost-effectiveness. In this blog, we will explore seven essential tips for optimizing Injection Molding Nitrile Rubber production, ensuring that businesses can enhance their operational efficiency while maintaining product quality and performance.

Key Factors Impacting Nitrile Rubber Properties in Injection Molding

When it comes to injection molding nitrile rubber, several key factors significantly impact the material's properties and overall production efficiency. One of the foremost considerations is the rubber’s formulation. The composition and quality of the raw materials directly influence the mechanical properties of the finished product, such as tensile strength, flexibility, and resistance to oils and chemicals. A well-balanced formulation will not only enhance durability but also improve processing performance during molding.

Temperature and pressure settings during the injection molding process are also crucial. Maintaining optimal temperatures for both the material and the mold can prevent defects such as warping or incomplete filling. Likewise, adjusting the injection pressure can impact the final product's density and surface finish. Properly managing these parameters helps ensure consistency and quality in the molded parts, ultimately leading to a more efficient production cycle. Understanding these factors enables manufacturers to fine-tune their processes and achieve high-quality nitrile rubber components.

Optimal Temperature Settings for Enhanced Nitrile Rubber Flow

When it comes to optimizing injection molding for nitrile rubber production, one of the critical factors that manufacturers must consider is the optimal temperature settings. The flowability of nitrile rubber significantly depends on the temperature at which it is processed. Maintaining the right temperature can prevent issues such as incomplete mold filling or surface defects, which can compromise the quality of the final product. A well-controlled temperature helps achieve a smoother and more efficient flow of the rubber material, resulting in a consistently high-quality output.

Setting the ideal temperature range requires careful calibration, as each formulation of nitrile rubber may behave differently under varying thermal conditions. Generally, preheating the mold can facilitate better flow, allowing the material to enter intricate mold designs without disruptions. Additionally, it’s crucial to monitor the melt temperature during the injection process; higher melt temperatures can enhance the material's flow characteristics but may also alter its mechanical properties. By systematically adjusting these temperature controls, manufacturers can significantly enhance the performance and reliability of their nitrile rubber components in various applications.

The Role of Injection Speed in Nitrile Rubber Production Efficiency

In the realm of nitrile rubber production, injection speed plays a crucial role in determining efficiency and product quality. A study by the Plastics Technology magazine indicates that optimizing injection speed can improve cycle time by up to 30%, significantly boosting overall productivity. The right injection speed not only ensures proper filling of molds but also minimizes defects such as flash and short shots, leading to higher production yields.

Tip #1: Adjust the injection speed based on the specific viscosity of the nitrile rubber being used. Lower viscosity materials benefit from higher injection speeds, whereas higher viscosity requires a more controlled approach to prevent degradation.

Tip #2: Monitor the temperature of the rubber throughout the injection process. Maintaining optimal temperatures can enhance flow properties, allowing for smoother mold filling and thereby reducing cycle times.

By focusing on these elements, manufacturers can achieve a delicate balance between speed and quality, ultimately driving down costs and improving market competitiveness. A comprehensive understanding of injection speed dynamics can yield significant advancements in nitrile rubber production efficiency.

Importance of Mold Design in Achieving Precise Nitrile Rubber Parts

In the realm of precision manufacturing, the significance of mold design cannot be overstated, especially in the production of nitrile rubber parts through injection molding. A well-thought-out mold design is fundamental to achieving the desired dimensional accuracy and surface finish, which ultimately leads to high-quality end products. The intricacies of mold geometry, including features such as cavity layout and cooling channels, play a crucial role in controlling temperature and pressure during the injection process, ensuring uniform material distribution.

Moreover, as industries increasingly adopt advanced manufacturing techniques like 3D printing, the insights gained from mold design can be valuable. While 3D printing offers incredible flexibility in producing complex components, traditional methods like injection molding remain essential for high-volume production of materials like nitrile rubber. By integrating modern technologies with tried-and-true methods, manufacturers can enhance efficiency and precision in creating intricate designs that meet the stringent requirements of sectors ranging from aerospace to medical applications. Thus, investing in robust mold designs can pave the way for more reliable and precise nitrile rubber components, keeping pace with the ever-evolving landscape of manufacturing innovation.

Reducing Waste and Scrap Rates in Nitrile Rubber Injection Processes

Reducing waste and scrap rates is crucial in nitrile rubber injection molding processes, not only for cost savings but also for improving overall efficiency. One essential tip is to meticulously review your material selection and processing parameters. Using high-quality materials that are specifically designed for your application can significantly minimize defects, which in turn reduces scrap rates. Regularly calibrating your machines and maintaining consistent temperature and pressure settings can also help in achieving better material flow and alignment during the injection process, thereby limiting waste.

Another key strategy involves implementing a robust quality control system. By integrating real-time monitoring of the injection process, manufacturers can quickly identify anomalies that could lead to increased waste. Inspecting parts at various stages and utilizing automation for quality checks can ensure that any defective items are spotted early in the production cycle. Additionally, training your operators on best practices and conducting regular workshops can instill a culture of quality and efficiency, further reducing the chances of scrap in nitrile rubber production.

Related Posts

-

Solutions for Sourcing the Best Butadiene Rubber Globally

-

Understanding the Benefits of Polyisoprene Rubber for Global Supply Chains

-

Finding the Right Manufacturer for Best Styrene Butadiene Rubber Products

-

Future Trends in Best Polybutadiene Rubber Market for 2025 and Beyond

-

7 Essential Benefits of Choosing Thermoplastic Rubber for Your Next Project

-

Exploring Innovative Alternatives to Polyisoprene Rubber in Modern Manufacturing